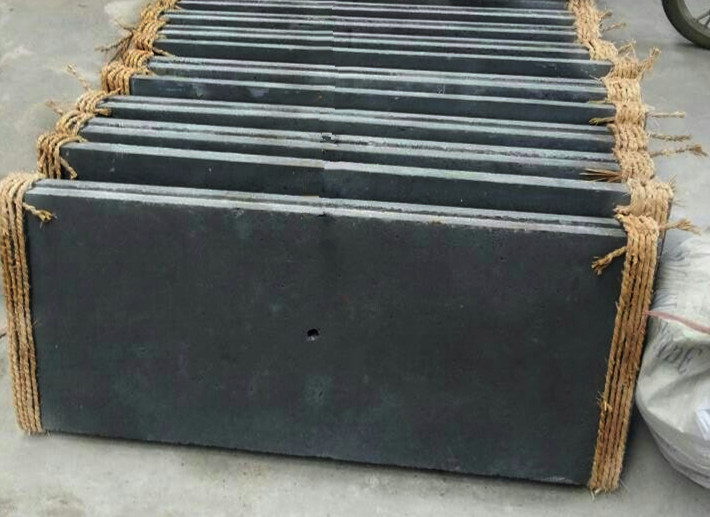

Self Bonded Silicon Carbide Brick Introduction

Self bonded silicon carbide brick with no binders belongs to high quality sintered refractory brick. Made from supreme black SiC, self bonded silicon carbide bricks have the characteristics of good wear-resistance, high thermal conductivity, great volume stability and good thermal shock resistance as well as great slag resistance. With so many advantages, silicon carbide bricks are extensively used in blast furnace, ceramic kiln, garbage incinerators.

Self Bonded Silicon Carbide Brick Sintering Mechanism

Silicon carbide, with strong atomic covalent bonds, has small gram molecule volume and great lattice energy. Therefore, silicon carbide molecule can withstand high temperature up to 2000℃. Silicon carbide molecule won’t evaporate until temperature reaches at 2273℃. Evaporation of silicon carbide molecule release huge energy and form great press. Silicon carbide brick just utilize the press to finish the self sintering process and has great mechanical strength. Further densification of silicon carbide brick embryo result from that gas phase molecules adhere to the crystal surface and promote the lattice growth.

Silicon Carbide Bricks Physicochemical Properties

| Item |

SiC, % |

| 50 |

70 |

80 |

90 |

95 |

| Bulk density, g/cm3 |

2.3 |

2.3~2.4 |

2.4~2.45 |

2.4~2.55 |

2.2~2.85 |

| Apparent porosity, % |

20 |

20~23 |

17~20 |

18~24 |

10~31 |

| Refractoriness under load, ℃, ≮ |

1500 |

1600 |

1650 |

1700 |

1700 |

| Cold crushing strength, MPa, ≮ |

50~80 |

80~90 |

≮90 |

≮90 |

≮90 |

| Thermal conductivity, 1000℃, W ▪(m ▪K)-1 |

4.07 |

6.16 |

8.49 |

10.58 |

12.79 |

Self Bonded Silicon Carbide Brick Application

Self bonded silicon carbide bricks mainly applied in high temperature industrial kilns, such as

Garbage incinerators

Blast furnace

Ceramic kiln

Electric furnace

Refinery furnaces